CIL installs the latest Nordson DAGE QUADRA 7 Pro X-Ray system

CIL maintains its pole position with Nordson DAGE QUADRA 7 Pro X-ray inspection addition at its BP2 Semiconductor packaging and volume PCBA facility.

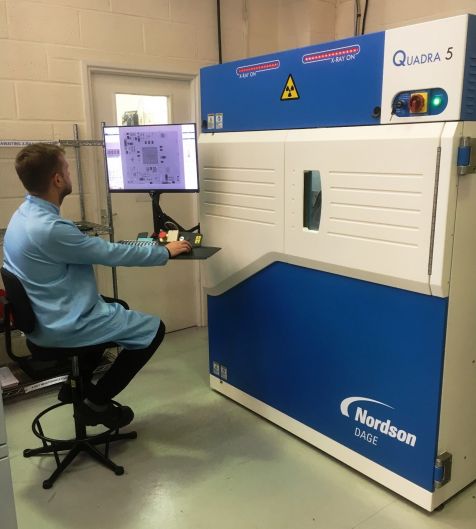

Custom Interconnect Ltd, (CIL), based in Andover, Hampshire, is a long-established electronics manufacturer engaged in producing some of the most technically challenging electronic assemblies in the UK. In 2018 CIL installed a DAGE QUADRA 5 X-Ray / CT Scan system at its CIL House facility, which now services its customers prototype and small to medium volume production. This latest QUADRA 7 Pro system has been installed at CIL’s BP2 Semiconductor packaging and volume PCBA facility, for the next generation of assemblies it is now manufacturing. This QUADRA 5 system is obviously still fully functional and will remain at the CIL House facility.

DAGE QUADRA 7 Pro X-Ray System at BP2 Facility

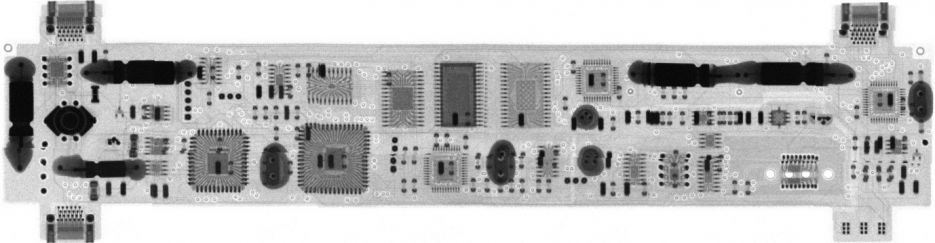

Resources must evolve and be updated constantly to keep pace with continuous development in component technology. For example, after 14 years’ successful experience with a DAGE XD7600 X-ray machine, in 2018 CIL decided to update to a Nordson DAGE QUADRA 5 system that is better-equipped to inspect the boards they then produced. Technology complexity has evolved, and more importantly geometries have reduced to such a level that 5 years later CIL has had to upgrade again to the very latest QUADRA 7 Pro system, the highest specification machine supplied by Nordson DAGE. As an example, when CIL first installed the DAGE XD7600 X-Ray system back in 2005, it was required for the assembly of BGA devices with solder ball sizes of typically 500 – 600um diameter. In 2018 the system was replaced by the QUADRA 5 as CIL was not only assembling BGA’s, but the smallest SMT devices were now wafer level chip scale packages (WLCSP) which typically have a solder ball size of 100um diameter. Now coming fully up to date, these same WLCSP devices now include Through Silicon Via (TSV) devices typically with a solder ball size of 45um. With CIL now finding itself being asked to assemble Silicon devices onto PCBA measuring 40mm x 15mm with TSV WLCSP devices of 30mm x 12mm with >4000 off 45um solder balls with absolutely zero opportunity for rework, all assembly and inspection equipment has to be upgraded. Having owned the DAGE QUADRA 5 for 5 years, its advanced technical capabilities were known, but CIL required the improved resolution of the very latest QUADRA 7 Pro system.

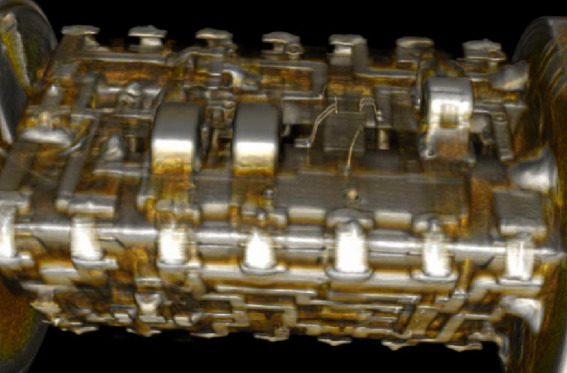

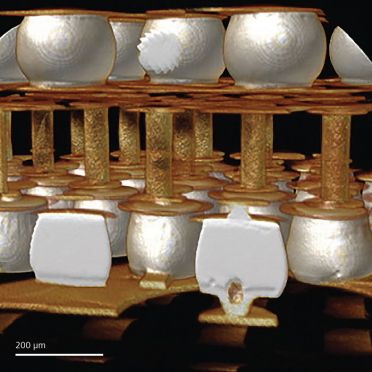

An advantage of the Quadra 5 is its computerised tomography (CT) capability. X-Plane builds X-ray 3D images comprising up to 1000 distinct slices or image planes of the component being inspected. A slice will remove obstructions above or below the plane of focus so that only the regions of interest remain. Defects such as interfacial voids, cracks, HIP and other solder defects can be found and measured easily. CT image cross-sections can be generated from anywhere on the sample tray without need for manual alignment. The addition of the CT sample stage provided with the CIL Quadra 5 adds additional full CT capability for small samples that require 3D reconstruction for detailed analysis. The system produces ultra-high quality images using Nordson Dage’s latest generation QuadraNT™ X-ray source, which is 10 times brighter and intrinsically more stable than conventional X-ray tubes. This is complemented by an Aspire flat panel detector, which combines 16-bit contrast with 3 megapixel resolution. Feature recognition down to 350nm and magnification up to 45,000 times allow visibility of the finest details and quick identification of defects.

The QUADRA 7 Pro has moved things on again at CIL. Instead of the 3 megapixel resolution of the QUADRA 5, the QUADRA 7 Pro has 6.5 megapixel resolution enabled by the new Onyx HL detector. Designed in-house by a team of semiconductor experts Onyx™ delivers state-of-the-art performance. Using world-class pixel specifications for low dose sensitivity & high saturation dose. Onyx™ has higher frame rates and lower noise, giving you faster clearer images. Feature recognition down to <100nm and magnification up to 68,000 times allow visibility of the finest details and quick identification of defects, so a significant improvement over the still excellent QUADRA 5 system.

3D CT Scan of complex micro-electronics assemblies

These advantages over the earlier machines help CIL to meet the inspection demands posed by today’s densely-packed PCBs and miniaturised components. However, the benefits extend beyond this; CIL’s assemblies find their way into extreme environments characteristic of their target markets. Medical devices / sensors, Automotive BEV & PHEV power electronics, advanced 5G GaN MMIC packaging and Oil & Gas applications can expose equipment to temperatures up to +195°C and this can create some unusual failure modes, many of which may not previously have been seen. CT scanning gives CIL a new ability to find these failures and their root causes. Once they’re found and understood, CIL can check for their presence in other products that are not necessarily exposed to the same environmental extremes. This pre-empts problems that could arise from a latent failure mechanism; one that slumbers for a considerable period until an unusually elevated stress level eventually triggers it. This may never happen for some products, but overall quality has nevertheless been further improved at an invisible as well as a visible level.

Accordingly, the system will support CIL’s current complement of eight SMT lines placing down to 01005 and all current IC package styles including BGA, LGA, QFN & WLCSP and associated inspection and test equipment including 3D AOI and flying probe test as well as the X-ray inspection resource. All manufacturing is under CIL’s Quality Management System, which is accredited to ISO9001:2015, AS9100 Rev D for Aerospace & Defence and ISO 13485:2016 for medical device manufacturing.

The QUADRA 5 is used on low-medium volume and prototyping projects housed at CIL House. The QUADRA 7 Pro is used at BP2 for semiconductor packaging and volume PCBA manufacturing facility for of its very latest assemblies. There is also the added benefit of assisting with CIL’s disaster recovery planning in that it now has two very capable X-Ray systems in two different manufacturing locations. As part of CIL’s scale up, it will very soon have four SMT lines at CIL House and the same four SMT lines repeated at its BP2 facility. This is further backed up by repeated 3D AOI, Flying probe test, PCB cleaners and auto CNC routers and both locations.

DAGE QUADRA 5 X-Ray / CT Scan at CIL House facility

Support provided by Cupio and Nordson Dage played a significant role in CIL’s considerations and decision. This had always been readily available throughout CIL’s 19-year ownership of the earlier machines. After the new system’s installation, Cupio provided on-site training in the new system features while updating the operators in the new inspection techniques. This mainly concerned the new user interface was very similar to the earlier machine’s, so the learning curve was reduced accordingly.

“Automatic inspection is fundamental to the integrity of the process, and, as much of our production uses ICs with under-package pinouts, an X-Ray system remains essential. For this, we trusted Cupio to provide the right solution” comments John Boston, “Yet this is just part of an extensive new capital investment programme designed to ensure we maintain the most advanced manufacturing capability in the UK. As TV business trouble-shooter Sir John Harvey-Jones once said, “If you buy second-hand, you’re immediately out of date”. By contrast, our policy is to continually invest in new equipment to retain our competitive edge and our insight into fault mechanisms, no matter how complex and highly-populated future board designs become.

“Ultimately, this investment allows us to live our 24/7 service culture; we believe in committing ‘whatever it takes’ to deliver reliable, timely and cost-effective solutions. Visitors to our manufacturing facility in Andover will be able to see for themselves our ability to deliver on our promise.”