Power Electronics for BEV & PHEV Vehicles

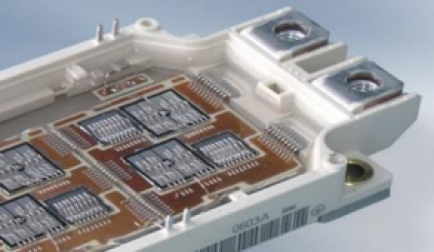

At Custom Interconnect Limited we have an unrivalled assembly capability to anywhere in the UK. With an extensive SMT PCB assembly facility, a state of the art high power die and wire bond assembly facility and a rapidly growing diagnostic equipment portfolio, our power electronics boast high quality production and superior technology for your battery engine vehicles (BEV) and plug-in hybrid electric vehicles (PHEV).

Our Power Electronic Semiconductor Packaging Capabilities

Interconnect Technologies include

- Silver Sinter die attach

- Silver Sinter top level interconnect

- Silver Sinter both low/pressure-less and High Pressure methods

- Eutectic Soldering

- Laser Soldering

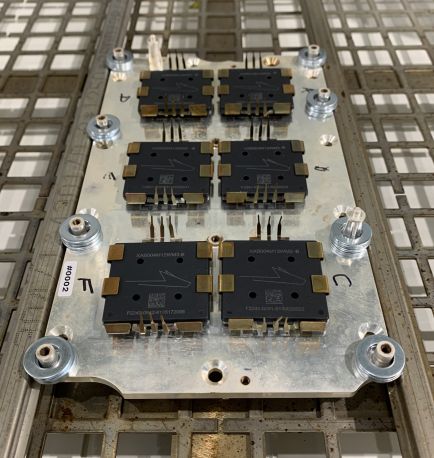

Packaged SiC types include

- ST Micro STPAK

- ST Micro SCTG011H75G3AG

- Wolfspeed WM4

- ON SEMI

- Hitachi

- Multiple other packaged types

Die types include

- Silicon Carbide SiC

- Gallium Nitride GaN

- IGBT

- Mosfet's

- Multiple other die types

Substrate materials include

- Alumina or other Metallised ceramics.

- DBC Direct Bonded Copper substrates

- AMB Active Metal Brazing substrates

- AiN substrates

- Copper

- Copper Tungsten

- Aluminium Backed & Aluminium

- Other high thermal materials

Heavy Gauge Wire Bonding includes

- Aluminium (Al) to 600um wire

- Aluminium (Al) to 2.00mm ribbon

- Copper to (Cu) 600um wire

- Copper to (Cu) 2.00mm ribbon

- Aluminium/Copper (AlCu) to 600um wire

- Aluminium/Copper (AlCu) to 2.00mm ribbon

Why work with CIL?

CIL's BP2 power micro-electronics packaging facility is at the forefront of the electric vehicle (EV) power revolution and is primarily used in Automotive BEV & PHEV drive train systems - we place IGBT & SiC packaged devices on a daily basis. Using Vacuum Assisted Vapour Phase reflow technology supplemented with the very latest DAGE QUADRA 7 Pro and DAGE QUADRA 5 X-Ray/CT scan systems complimented with Nordson GEN3 Scanning Acoustic Microscopy (CSAM) machines mean we can offer extremely low solder / sinter voiding which is critical in high power electronic assembly for this market.

We have a specialist knowledge unlike our competitors due to our experience in other fields. For example, based on 15 years of extensive component and assembly knowledge gained from the Oil & Gas downhole industry, many of the assemblies we produce have to operate at 150 °C. These temperatures are being generated in SiC based BEV Inverters.

Centred around Silicon Carbide (SiC) and Gallium Nitride (GaN) power packaging using Silver Sinter die attach techniques, CIL has the most advanced capability in the UK. Top level connectivity is normally achieved with Heavy Gauge Aluminium or Copper wire/ribbon with a wire diameter of up to 600um. We are also involved with Tier 1 OEM's Research looking into low cost and high reliability methods of connection that are not wire bonded. This has ultimately culminated in CIL being selected by both

BMW and McLaren on the APC15@FutureBEV consortium to develop SiC based power switches and associated drive electronics/sensors inverters to be used on their future vehicles. This project success was repeated with

APC20 EleVAIT, whereby CIL is now working with a consortium headed by Jaguar Land Rover (JLR) again working on future SiC power modules and control electronics. CIL is also working with a number of other customers in this sector and multiple other sectors using IGBT / SiC / GaN based power electronics.

All of this assembly capability is backed up with wire bond pull and die shear test capability. The detection of voiding under power devices is critical, so CIL uses its in-house Dage QUADRA5 X-ray / CT Scan system and will soon also have in-house Scanning Acoustic Microscopy (C-SAM) capability. Our capabilities include:

FR4 ALL THICKNESSES AND FR4 Hi TEMPERATURE

FR4 HEAVY COPPER TO 6oz, 8oz, 10oz & 12oz Thicknesses

ALUMINIUM, ALUMINIUM CLAD & COPPER CLAD PCB’s

Get in contact with a member of our friendly sales team for more information on our BEV & PHEV power electronic capabilities today.