WBG Power Device SiC & GaN

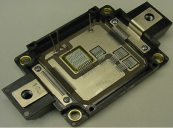

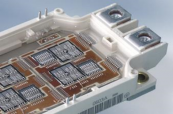

CIL's Power micro-electronics packaging facility is at the forefront of the EV power revolution primarily used in Automotive BEV & PHEV drivetrain systems. Centred around Silicon Carbide (SiC) and Gallium Nitride (GaN) power packaging using Silver Sinter die attach techniques, CIL has the most advanced capability in the UK. Top level connectivity is normally achieved with Heavy Gauge Aluminium or Copper wire/ribbon with wire diameter up to 600um and CIL is also involved with Tier 1 OEM's researching low cost/high reliability methods of connection that is not wire bonded. This has ultimately culminated in CIL being selected for two Advanced Propulsion Centre (APC) projects working with the following Automotive OEM partners

APC15 @FutureBEV - BMW & McLaren, to develop SiC based power modules and associated SMT based drive electronics / sensors for use on their future vehicles.

APC20 EleVAIT - Jaguar Land Rover (JLR), to develop SiC based power modules and associated SMT based drive electronics / sensors for use on their future vehicles.

CIL is also working with a number of other OEM customers in this sector and multiple other sectors using IGBT / SiC / GaN based power electronics

Interconnect Technologies include

- Silver Sinter die attach

- Silver Sinter top level interconnect

- Eutectic Soldering

- Laser Soldering

Die types include

- Silicon Carbide SiC

- Gallium Nitride GaN

- IGBT

- Mosfet's

- Multiple other die types

Substrate materials include

- Alumina or other Metallised ceramics.

- DBC Direct Bonded Copper substrates

- AMB Active Metal Brazing substrates

- AiN substrates

- Copper

- Copper Tungsten

- Aluminium Backed & Aluminium

- Other high thermal materials

Heavy Gauge Wirebonding includes

- Aluminium (Al) to 600um wire

- Aluminium (Al) to 2.00mm ribbon

- Copper to (Cu) 600um wire

- Copper to (Cu) 2.00mm ribbon

- Aluminium/Copper (AlCu) to 600um wire

- Aluminium/Copper (AlCu) to 2.00mm ribbon

All of this assembly capability is backed up with wirebond pull and die shear test capability. The detection of voiding under power devices is critical, so CIL uses its in-house Dage QUADRA5 X-ray / CT Scan system and in-house Scanning Acoustic Microscopy (C-SAM) capability.

If you’re interested in power electronics, get in touch with the business development team today and see what Custom Interconnect can do for you.