Custom Interconnect Ltd joins with CSA Catapult for Project GaNSiC

Custom Interconnect Ltd and CSA Catapult help drive Electric Transport Revolution with developing novel ways of depositing Silver Sinter paste for WBG applications in Project GaNSiC

Named GaNSiC, the project stems from the UK Research and Innovation’s (UKRI) ‘Driving the Electric Revolution’ challenge and brings together Custom Interconnect Ltd (CIL) and Compound Semiconductor Applications Catapult (CSA Catapult). It is set to develop novel ways of applying Silver Sinter pastes to Wide Band Gap semiconductors such as Silicon Carbide (SiC) and Gallium Nitride (GaN) devices to optimise their thermal coupling and solve complex power module assembly.

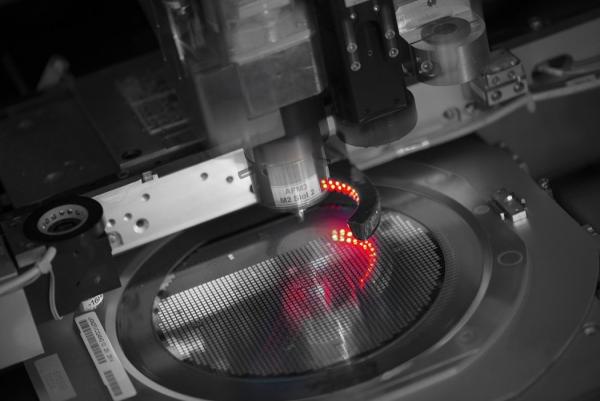

Increasingly the adoption of WBG semiconductors that include Silicon Carbide (SiC) and Gallium Nitride (GaN) devices are revolutionising electric powered transport. Up until very recently these devices were bonded to a substrate using conductive epoxies or solders. The power densities of these WBG devices when compared with traditional Silicon (Si) based semiconductors such as IGBT’s have seen a step shift away from traditional methods of die attach to exclusively Silver Sinter die attach methods. These devices were also traditionally wire bonded using heavy gauge wire/ribbon bonding which is both expensive and over a long period of time, unreliable especially at high temperatures. Going forwards to assist the next generation of Power Electronics, Electric Machines and Drives (PEMD), these devices will be double sided silver sintered. However, the application of the silver sinter paste is currently performed using traditional dispense / printed methods. Project GaNSiC is a 9-month project to develop a unique method of silver sinter paste deposition that is not limited by dispense / printed methods. This new technology will allow enhanced thermal coupling of WBG semiconductors in power modules and result in smaller, lighter and more efficient PEMD devices.

John Boston, Managing Director of CIL, commented: “We are extremely proud to be part of this pioneering project that will hopefully lead to better efficiency in all-electric engines and help accelerate the adoption of Automotive BEV and e-planes. We are already jointly working with CSA Catapult on the APC15@FutureBEV project to develop SiC based power modules for BMW. And we are also the manufacturing partner on numerous WBG projects. As the lead partner in GaNSIC, CIL will design and manufacture both SiC and GaN assemblies. The CSA Catapult will provide their circuit design and testing expertise to develop innovative testing and qualification process for realising the prototypes.” Project GaNSiC started in November 2020 and is now due to run for nine months. It is funded by UK Research and Innovation.

Martin McHugh, CTO and Acting CEO at the CSA Catapult said: “CSA Catapult was created to further the adoption of compound semiconductors in future technologies and we are very pleased to be working on this wide band gap project. We can see that the project will help to improve much-needed efficiency in future electronic vehicles which will further enable the trend in electrification of transport and help reach UK government targets of 2030. The project will also help accelerate the development of the UK supply chain for the transport of the future leading to a smoother and faster journey from innovation to marketplace.”

About Driving the Electric Revolution

Driving the Electric Revolution started in 2019 and is funded by an £80 million investment from the Industrial Strategy Challenge Fund, run by UK Research and Innovation. Working across all sectors the challenge aims to make the UK a global leader in the manufacture of core technologies which support electrification: Power Electronics, Machines and Drives (PEMD).

About Custom Interconnect Ltd

Custom Interconnect Ltd (CIL) is a global provider of engineering solutions for mission critical applications. CIL manufacturing facility based in Andover UK already has the most advanced electronic assembly facility in the UK. Ranging from 6 SMT lines, 3D AOI, flying probe test, X-Ray/CT-Scan, Laser depanelling, Vacuum Assisted Vapour phase, 7 auto wire-bonders and 3 auto die bonders, CIL is now about to install C-SAM Scanning Acoustic microscope to ensure it continues to manufacturer world class products for its customers. The company operates in a multitude of industries that include Automotive BEV/PHEV, Aerospace and defence, medical, industrial, Transportation and many other sectors. Products designed and manufactured include SiC and GaN based power modules and control electronics, power management devices, communication systems, sensors, and medical electronics

For more information about CIL visit www.cil-uk.co.uk

About CSA Catapult

Compound Semiconductor Applications (CSA) Catapult is focused on bringing compound semiconductor applications to life in three key areas: the road to Net Zero, future telecoms and intelligent sensing.

CSA Catapult is a Not for Profit organisation headquartered in South Wales. It is focused on three technology areas: Power Electronics, RF & Microwave and Photonics. As well as the three technology areas, CSA Catapult is also working in Advanced Packaging for these high-power innovations.

The next wave of emerging applications will have an enormous impact on our lives. Compound semiconductors will enable a host of new and exciting applications in the electrification of transport, clean energy, defence and security and digital communications markets.

CSA Catapult exists to help the UK compound semiconductor industry grow and collaborates across the UK and internationally.

For more information about CSA Catapult please visit www.csa.catapult.org.uk